Prusa MK4

|

Prusa MK4

|

|

|---|---|

|

|

| Status: Active | |

Superusers

- Reese Snook (rsnook@terpmail.umd.edu)

- Ivan Penskiy (ipenskiy@umd.edu)

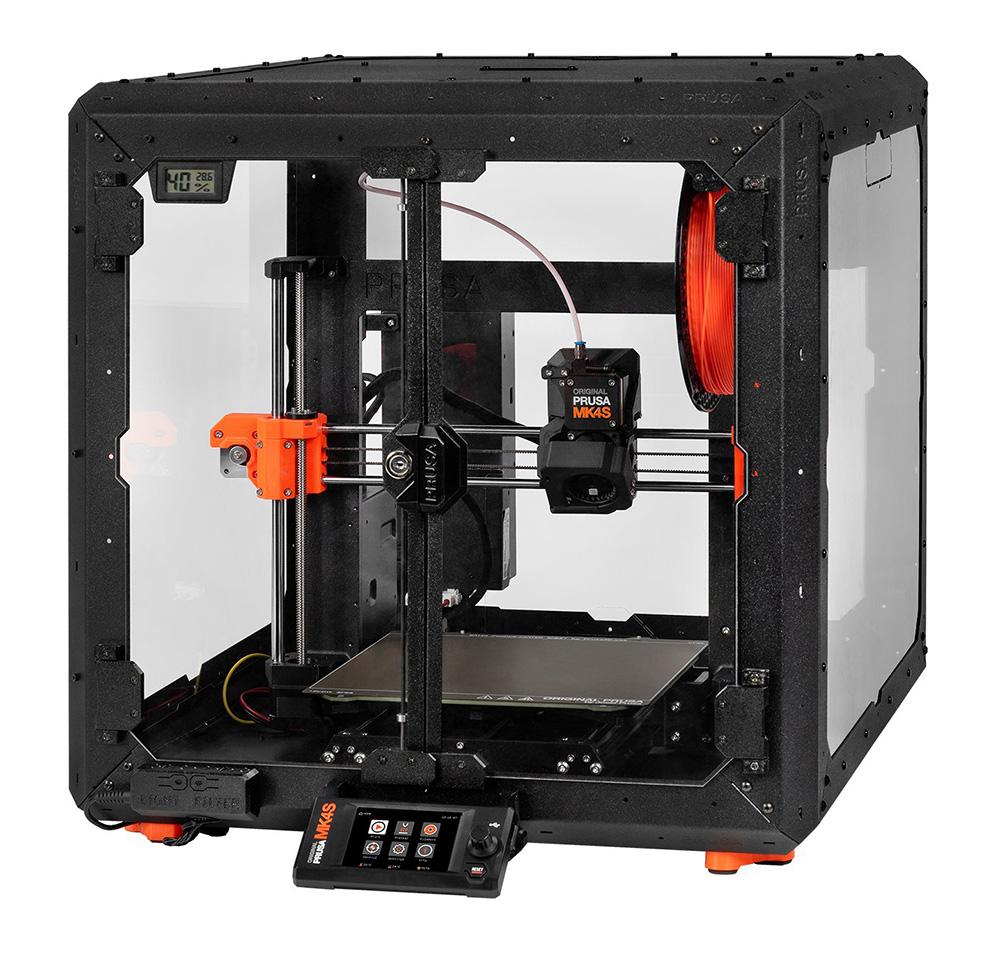

Overview

Prusa MK4 is a high-precision, user-friendly fused deposition modeling (FDM) 3D printer designed for reliability and ease of use. With a removable PEI-coated spring steel build plate, automatic mesh bed leveling, and silent operation, the MK4 delivers consistent and hassle-free prints. It supports a wide range of materials, including PLA, PETG, ABS, and flexibles, making it ideal for educators and professionals alike. Additionally, its open-source design allows for extensive customization and upgrades.

Location

E.A. Fernandez IDEA Factory (Bldg. 228), room 3119.3D printer specifications

| Max print volume (W × D × H) | 250 × 210 × 220 mm (9.84 × 8.3 × 8.6 inch) |

| Layer height | 0.05 - 0.35 mm standard layer height: 0.20mm |

| Supported materials | – common: PLA, ABS, TPU, PETG, ASA – uncommon: HIPS, PC, TPE, NYLON – with supervisor approval: PP, PVA |

| Maximum print head temperature | 290 °C |

| Maximum heated bed temperature | 120 °C |

| Accepted file types | .stl, .step, .3mf, .obj, .amf |

Important documents and useful links

- Official user guide

- Manufacturer technical specs

- Prusa slicer guides landing page

- Prusa MK4 knowledge base

- Terrapin Works Prusa slicer Dozuki guide

Reservation

Prusa MK4 must be reserved before using. The reservation is done using the Google calendar. Users will be able to reserve the equipment personally after attending the RAL lab orientation and then following the steps below to gain access to the equipment.

TBD

Video demonstration

The following videos demonstrate capabilities and the some aspects of operating the Prusa MK4 printer:Important reminders and safety

- Some parts of the printer get very hot during operation and take a while to cool down. Be careful when removing the printed parts or doing work inside the printer.

- Make sure to log the print and the amount of material used.

Designs can be made in any software capable of saving models in STL format (e.g. Onshape, AutoCad, SolidWorks, ProE, etc.). The on site computer station is meant for operating lab equipment only. Do not work on your CAD models here, your files can be brought over on a flash drive or wireless method.

Remember to set the appropriate tolerances in your STL files: tolerances should be smaller than the smallest feature in your design. Don't make tolerances much smaller than 3D printer resolution. Also, be mindful that small tolerances produce larger files.

- Guide to tolerancing for 3D prints

- Design for 3D printing guide by All3DP

- Visual troubleshooting guide

3D printing conceptual guides

- 3D printer anatomy, youtube video

- 3D printing basics, youtube video

TBD

TBD

TBD

Shutting down procedures

- Ensure that no active print jobs are running.

- Flip the main the power switch located at the lower right back.

Gaining access to equipment

Read the printer's user manual and contact the lab manager (ipenskiy@umd.edu).